23/06/2025

IDAERO joins the DOZE project to drive the zero-emission aerostructures of the future

IDAERO is part of the consortium behind the DOZE project (Advanced Manufacturing of Multifunctional Aerostructures for Zero-Emission Aircraft), a strategic initiative focused on developing lightweight, multifunctional, and sustainable structural solutions for the aviation of the future.

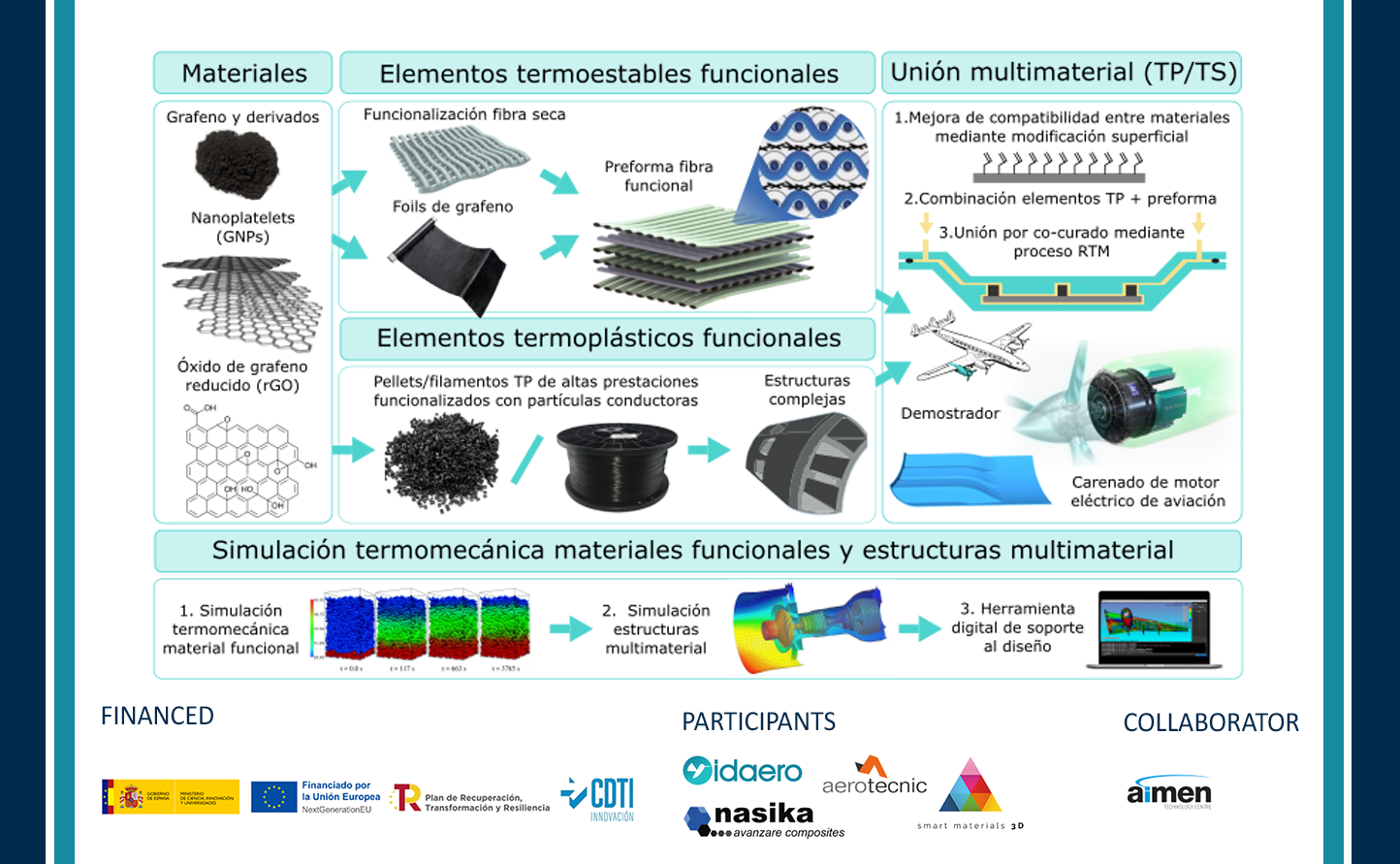

The main objective of DOZE is to explore new concepts for manufacturing advanced aerostructures that combine thermoplastic and thermoset composite materials, integrate thermal management functionalities, and can be produced through sustainable out-of-autoclave processes. The project aims to reduce both the weight and environmental impact of future aircraft platforms, contributing to the European ambition of achieving zero-emission aviation.

To achieve this, the project is structured around three main lines of research:

- Advanced Functional Composites

New composite materials with enhanced thermal properties will be developed through the use of additives such as graphene, while also seeking to reduce structural weight. These materials will enable efficient thermal management without compromising mechanical performance, playing a key role in the evolution toward more efficient and sustainable aircraft. - Multimaterial Structure Manufacturing

The project will combine technologies such as 3D printing of thermoplastics and resin transfer molding (RTM) of thermosets in innovative “one-shot” co-curing processes. This approach will allow different materials to be integrated in a single operation, eliminating additional assembly steps and reducing waste. The use of thermal pastes in metal-composite joints will also be explored to maximize thermal efficiency. - Advanced Simulation for Optimal Design

Simulation tools will be used to predict and optimize the functional behavior of the new materials and multimaterial joints. This will ensure that the structures meet the stringent requirements for strength, weight, and functionality demanded by the aerospace sector.

The tangible outcome of the project will be the DOZE demonstrator, based on an electric engine fairing section, built using lightweight multimaterial composite structures with integrated thermal management capabilities.

At Idaero Solutions, we will contribute our expertise in advanced engineering, simulation software development, and structural design to support the definition, modeling, and validation of these new solutions. Our participation in DOZE reinforces our commitment to innovation and to the development of technologies that chart the course toward a cleaner, safer, and more efficient aviation industry.

A strong and complementary consortium

The DOZE project is led by AEROTECNIC, an aerostructure manufacturer, and includes the participation of Idaero Solutions as a provider of advanced simulation tools; SMART MATERIALS 3D, a specialist in functional materials for 3D printing; and NASIKA, focused on the development of graphene-based composites.

This industrial consortium is further supported by the collaboration of AIMEN Technology Centre, an international leader in functional materials and advanced manufacturing processes.

The consortium partners represent key stakeholders across the project’s value chain and bring extensive experience in their respective fields, as well as strong positions in both the aerospace sector and other advanced technology industries.

DOZE is a project funded by the Centre for the Development of Industrial Technology (CDTI) and supported by the Ministry of Science and Innovation, under the Recovery, Transformation and Resilience Plan, financed with Next Generation EU funds.

More information on the official DOZE project web site